With the advent of Industry 4.0, data availability in the manufacturing industry is ever increasing in terms of volume and in various formats, semantics, quality, such as production line sensory data, environmental data, machine tool parameters, etc. This offers great potential to improve process and product quality sustainably by capitalizing on Big Data technology to implement use cases to make factories “smarter”. It also poses a great challenge to make proper use and interpretation of said data, which may lead to improver root cause analysis or not taking appropriate actions in due time.

Machine learning has become a key technology priority for manufacturers to monetize information for enhanced productivity, transform their business models and shift their operations accordingly.

Building a business case in manufacturing, however, may be challenging. The same is true of selecting the best technological partners and planning for success.

OREDATA can provide your enterprise with the support needed to handle the high dimensionality, complexity, and dynamics required to better understand customer requirements, quality improvement initiatives, manufacturing cost estimation and/or process optimization, etc. in a dynamic business environment where today’s manufacturing companies are affected by macro-economic and supply-chain uncertainty.

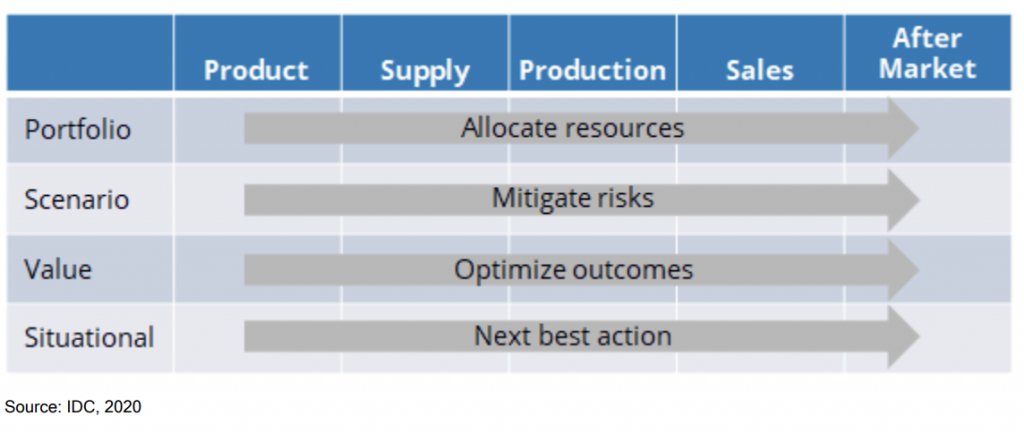

We help digitally transform enterprises and support the sustainable management of manufacturing data repositories with the appropriate IT infrastructure, integrations and implementation of the right machine learning tools and AI systems for monitoring and control, scheduling and diagnostics, etc. For instance, the digital twin is an analytic environment that creates a closed-loop decision-making model for any domain in the value chain and serves to bridge the strategy to execution gap. The model is built to connect the decisions made at the most strategic level to those being made in real time at the operational level (see Figure 1).

There are four analysis types done for every domain within a manufacturing enterprise:

– Portfolio analysis: Executives determine the right mix of products, customers, suppliers, assets, people, etc. to allocate resources

– Scenario analysis: Seniors assess possibilities to identify where the organization is vulnerable to mitigate risks

– Value analysis: Plan & evaluate counter-balancing outcomes (e.g., inventory levels versus order fulfillment rates) to optimize outcomes

– Situational analysis: Evaluate real-time to determine the next best action

In these models, business policy or rules flow down, while information flows up. The premise is to create a complete closed-loop decision process which, combined with the means of operational processes like RPA (the digital thread), provide the digital platform necessary to make the promise of digital transformation a reality.

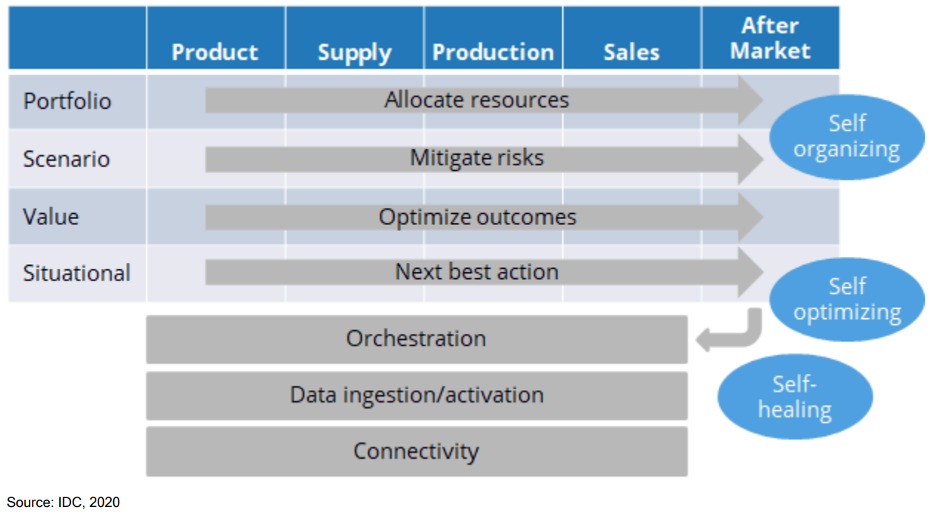

The digital thread, which is realized at the process level, frequently serves as the focal point of strategies for implementing IoT technology. Basically three levels are present. Devices and their corresponding connectivity form the basis. Data ingestion and activation layer is the subsequent layer. The purpose of this layer is to send down instructions to the devices as well as to gather and arrange the data flowing from the devices. Process orchestration is the highest level activity because it puts the data and action into the context of a process. The digital twin and digital thread come together when the next best action coming from the situational analysis directly communicates with the process orchestration to instantiate the action (see Figure 2)

OREDATA’s team of data engineers and scientists help derive knowledge out of your existing data and develop models for prediction, detection, classification, regression, or forecasting to address your unique optimization, control, and troubleshooting challenges. We aim to render your capabilities and supply chains more agile and flexible and enable innovation in products, services, and processes with the latest enterprise-grade and open-sourced solutions available in the market to optimize operational efficiency, fortify supply chain resiliency, deliver omnichannel product experiences and ensure regulatory compliance.

Reduce cycle time and scrap, improve resource utilization and manage change by making use of powerful ML/AI tools for continuous quality improvement and adapting your processes in an automated manner within your dynamic manufacturing system. OREDATA is here to help digitize processes and integrate your multiple systems to drive and keep up your manufacturing business with today’s global digital transformation.